People have asked me many times

what goes into the

Gadgetman Groove Modification Process,

so I thought I’d walk you through it

from the back end.

You know, the stuff nobody sees.

So here goes…

Before I can even THINK about starting,

I get myself set up with some 90 proof!

I’m a Coffee Snob.

Fresh ground French Roast.

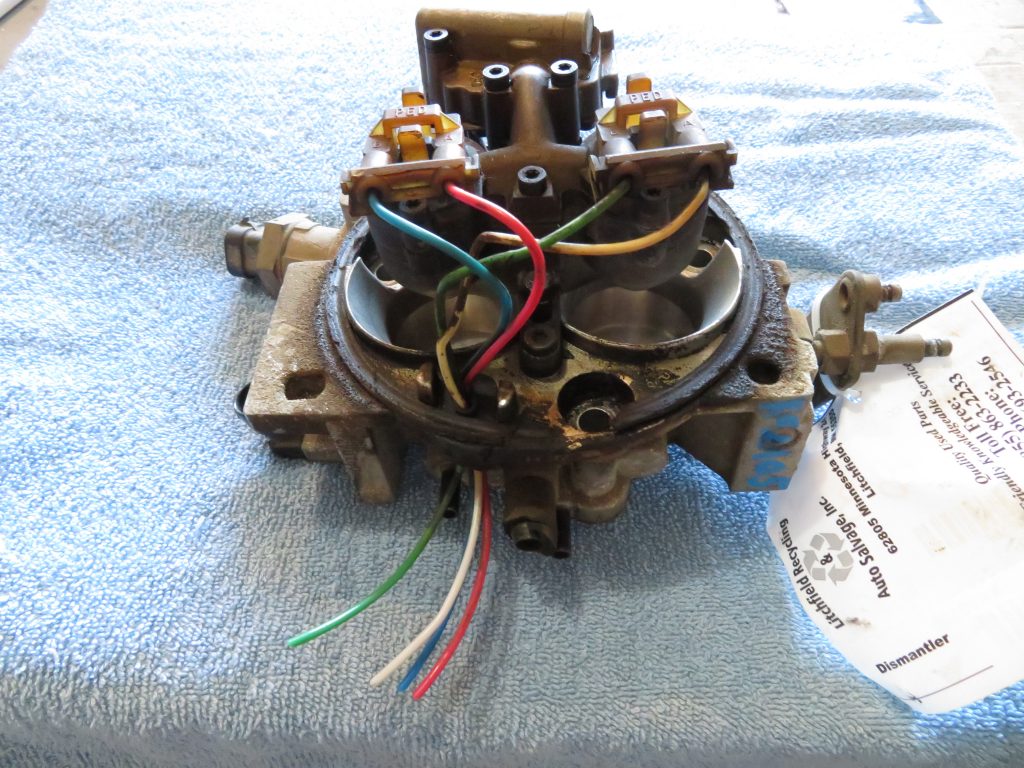

The first thing we do is give it a visual inspection

to make sure it’s working correctly

and the assorted sensors look good.

If anything is off, we decide what to do,

whether it’s return the item and start over,

or advise the client of any changes

that may required.

Time required: 5 Minutes.

Next, we check out the device more thoroughly.

Time required: 5 to 15 minutes.

One of the many precious gifts I’ve received from Loreta.

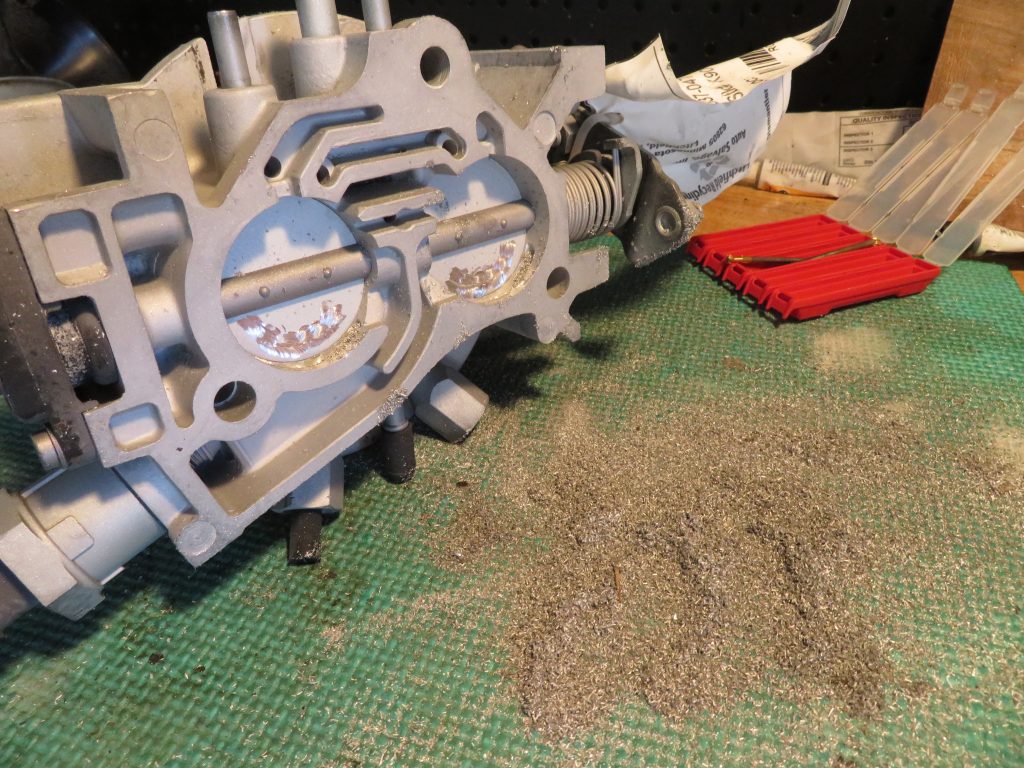

Once we’ve done the inspections,

we start the process by

removing the worst grunge and garbage.

Some is quite stubborn, requiring additional time.

Time required: 5 to 20 minutes.

Uh-oh! Time for more coffee!

Before it’s first visit to the cleaning cage,

we block off any sensitive areas to ensure no sand gets into them.

It wouldn’t do to have the injectors blocked when it’s fired up!

Next, it’s time to visit the sandblasting cage.

It’s taken months to develop my skills with this simple device!

Time required: 15-45 Minutes.

Once it’s had a thorough cleaning,

it looks a LOT better and is ready for the modification.

Next, we select the proper sized bit and

start the actual modification.

Then we machine the actual Groove

into the assembly just downstream

and as close to the throttle plate as possible.

All machine work is done by hand.

And here’s what it looks like with The Groove completed.

Time Required: 15-30 minutes.

In some cases (not this one) the walls where The Groove is applied is thinner than others.

This is checked by shining a light inside The Groove,

looking for light seeping through to the outside.

In the event I spot a potential leak,

I apply JB-Kwik to the outside

(if possible)

to ensure there are no leaks.

Sometimes, I miss a spot.

So I ask every customer to check my work, and apply additional JB-Kwik if needed.

It doesn’t happen OFTEN, but you should

ALWAYS CHECK MY WORK!

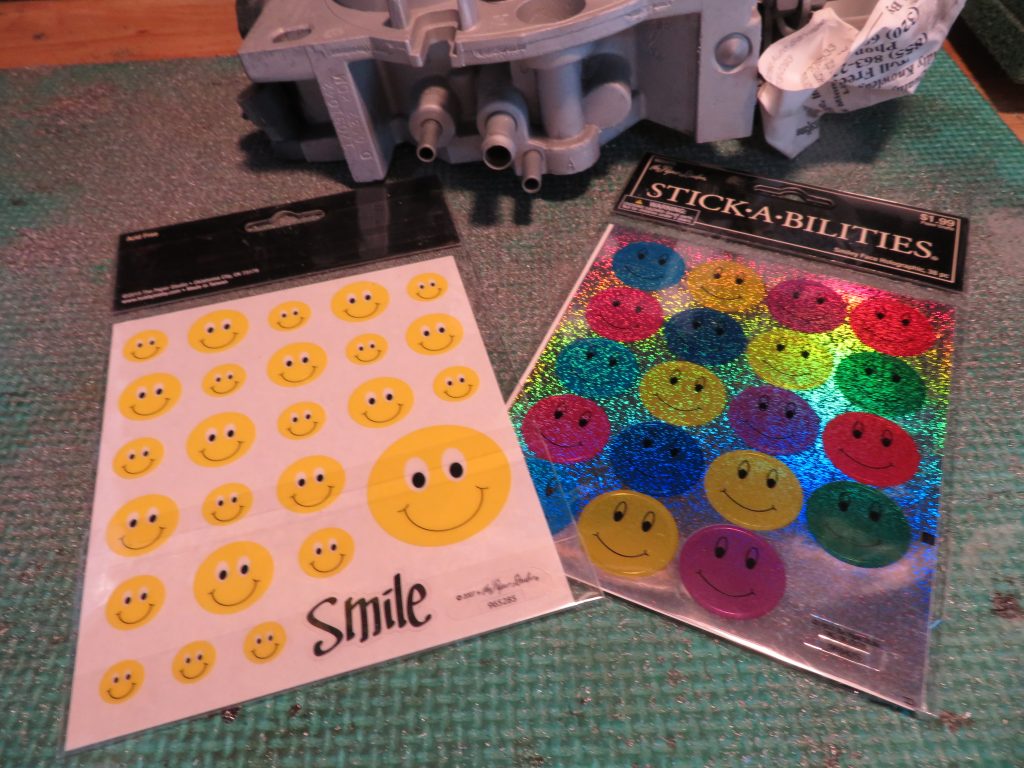

Once The Groove is applied,

it goes BACK into the cage

to knock off any grease spots I may have missed

and to polish the plates.

Then the all-important finishing touch is applied.

SMILEY FACES!!!

Today, it was Sparkly, HAPPY blue!

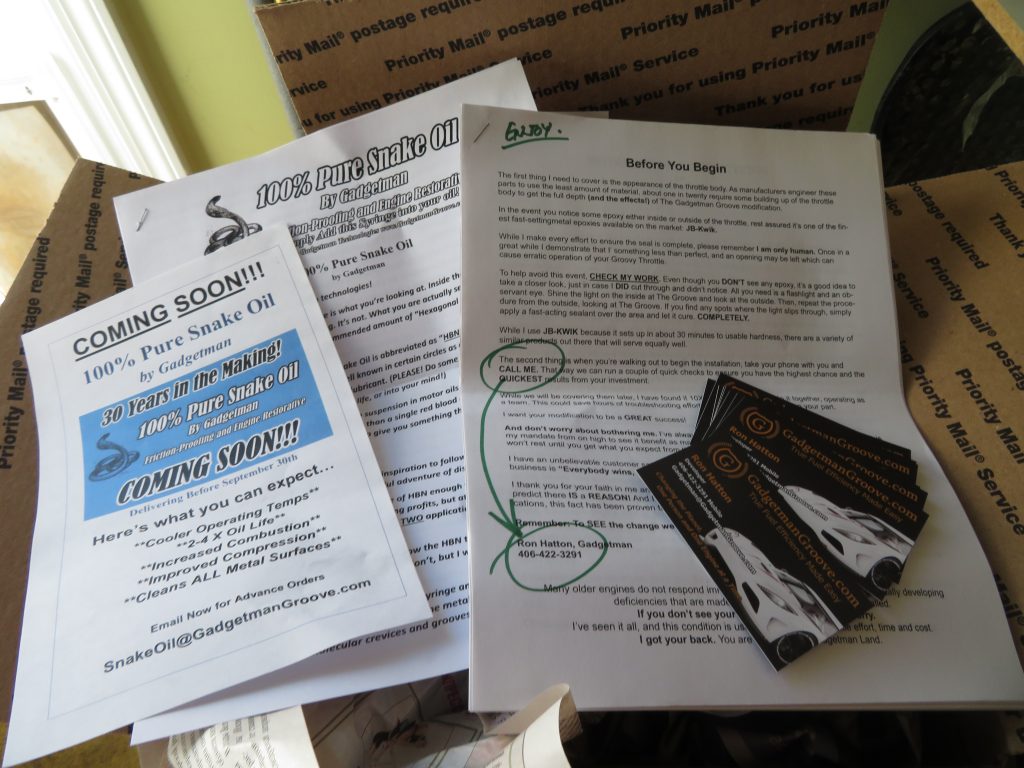

From here, it’s on to the packing station.

Once I read the news, of course!

Once we’ve packed the throttle body TIGHTLY to avoid damage during shipment,

we add the assorted paperwork.

For this customer, I’m including a little surprise.

A trial application of

100% Pure Snake Oil

so I add some information on that

along with the Installation Instructions

Add a few business cards in case they want to

talk to others about my work,

and it’s ready for shipment.

Time required: 15 Minutes.

This is what we go through with every order.

So, the investment of time we put into

each throttle body gives you

the best we can deliver

ranges from about

One hour to

TWO and a HALF

hours!

If you’re ready to “Get YOUR Groove On”

Start the Ordering Process Now!